Your heat process is too slow? IR boosters are the solution!

If the output of an existing plant is to be increased or an old plant limits the production speed, many plant operators are faced with a problem. A new plant costs is expensive and often there is not enough space to expand the existing plant. Infrared boosters are the solution. They can be integrated fast and simply into an existing production line.

There are electric and gas-catalytic infrared boosters. The specific framework conditions of product and process determine the selection. In practice, different combinations are used for boosters. For example, infrared modules in front of a hot air oven or electric infrared booster together with a gas-catalytic infrared oven.

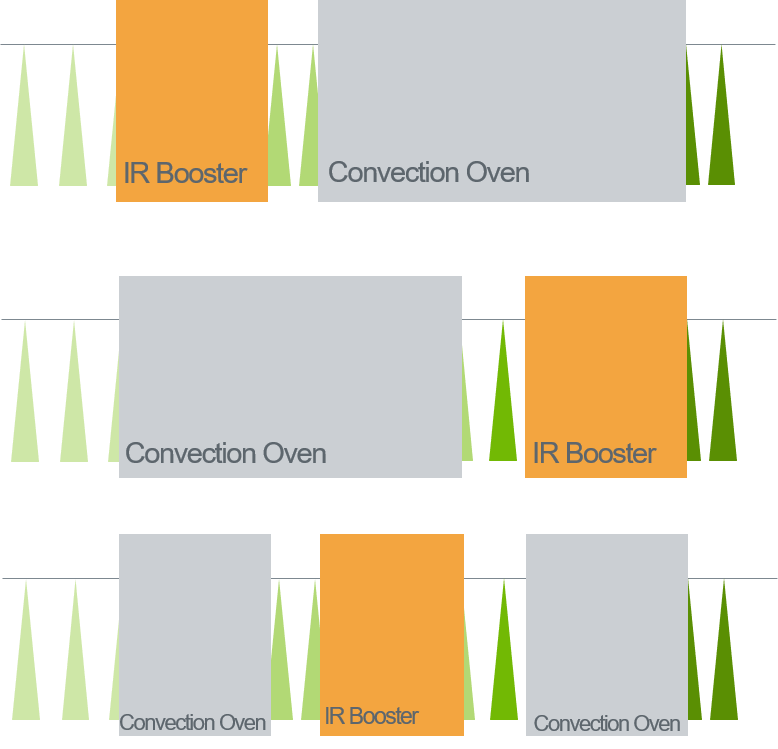

Next to the classic booster, an infrared module placed in front of another heating module, a booster can also be placed after the existing oven or in between.

Applications:

- Pre-Heating

- Gelling

- Curing