Drying water-based coatings or inks is demanding. It is worth taking a close look and adapting the dryer precisely to the process and the customer's specifications.

Infradry® - Infrared dryer for water-based inks and coatings

See in our video an example of efficient drying with Infradry® systems:

Infrared heat technology is well suited for targeted drying of water and water-based inks and offers many advantages not everyone is aware of:

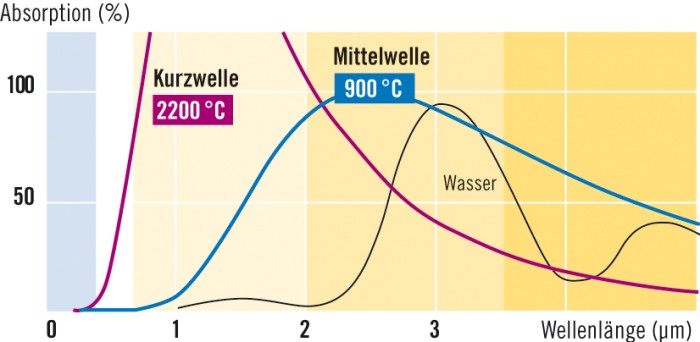

What we often hear: We need NIR drying solutions for drying inks and coatings.

What we say in response: We offer NIR - but other wavelength ranges turn out to be more effective quite often.

What we often hear: Infrared burns black print areas while yellow areas are still wet.

What we say in response: This can be prevented by adapting the IR system to the coating.

What we often hear: If moisture is not removed well in a dryer, condensation may form on other components.

What we say in response: Air management is important for drying processes with infrared heat.

Infradry® Systems - High-performance infrared dryers for water-based paints, varnishes and printing

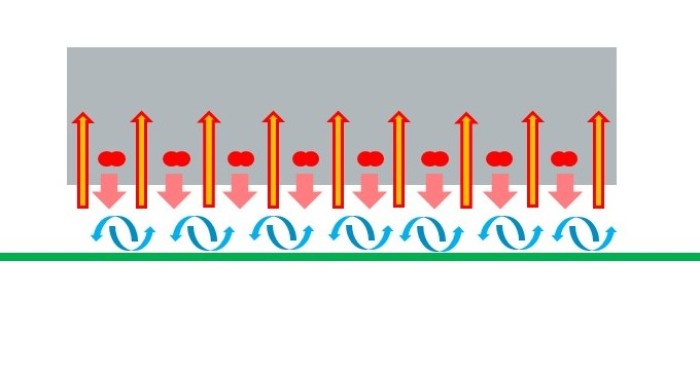

Infradry® modules are a clever combination between infrared heating and air management.

Conventional drying might cause condensed water in cooler machine parts. Infradry dryers are removing moisture directly in the process area.

Your advantages with Infradry® systems:

- Very efficient drying

- Modular design, enabling simple lamp replacement

- Plug & play installation

- Configurable interfaces

Would you like to discover how Infradry® systems can help to increase production speed?