The booster section rapidly brings the product up to temperature allowing line speeds to be increased accordingly. For some products this can equate to savings of up to 50% of the time required to dry or cure the coating.

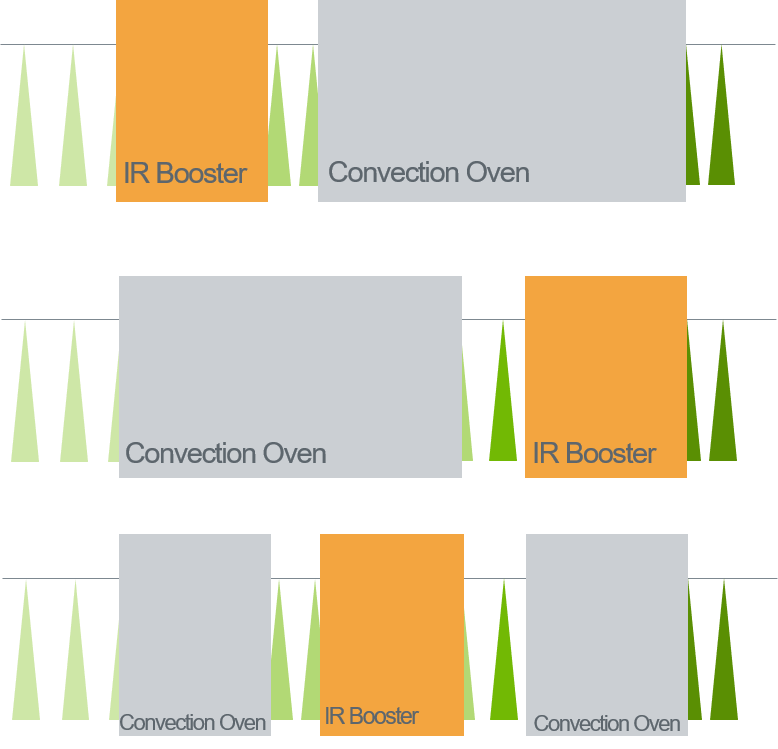

Next to the classic booster - an infrared module placed in front of another heating module - a booster can also be placed after the existing oven or in between.

Your advantages using infrared boosters:

- Saving time by faster heating

- Saving space through shorter drying distances

- Saving energy through fast reaction times