Books, brochures, labels, forms, foils and packages are printed and coated with protective paint using different methods.

However, what they all have in common is that the printing ink needs to be completely dried or cured before the products can be stacked, cut, folded or otherwise processed.

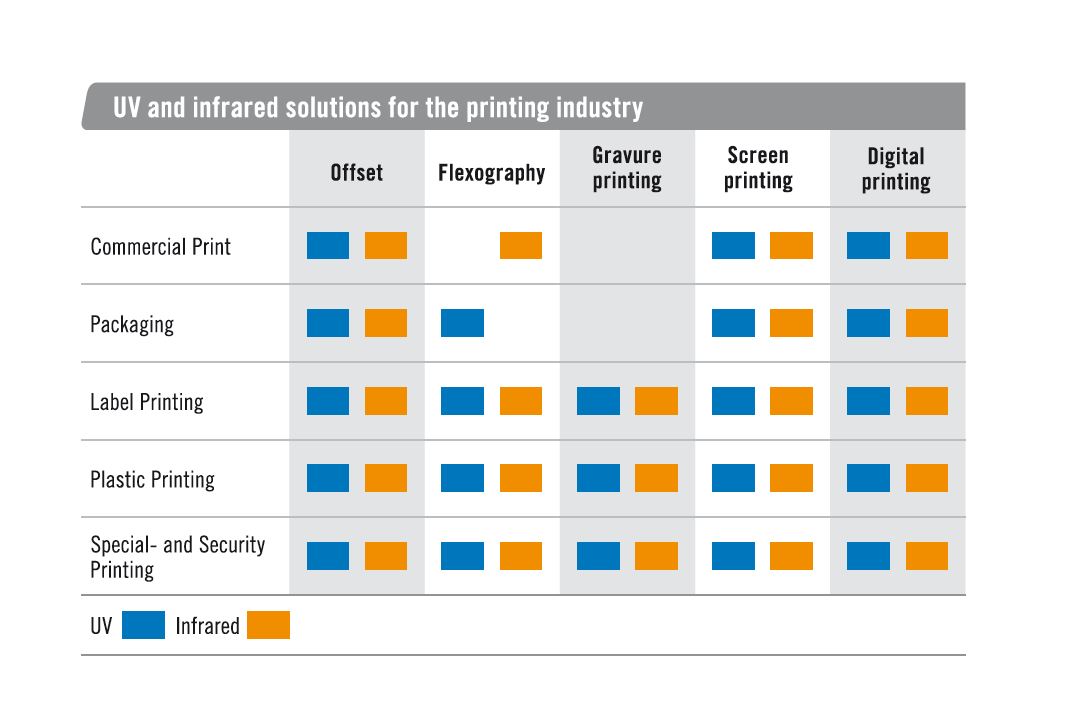

Depending on the paint, UV lamps or IR emitters, or a combination of both, are used for drying or curing. The UV and IR solutions are precisely adjusted to the individual printing process requirements, to work as efficiently as possible.

Drying and curing of printing inks and digital printing

Drying and Curing with Infrared Heat and UV Technology

Make use of the intelligence of the infrared heat technology. In contrast to conventional thermal methods, infrared emitters transmit high amounts of energy within a short period of time. Heat is applied precisely where and just as long as it is needed for your process, it dries the printing ink and spares both paper and machines.

Application examples:

- Digital printing for personal mailings

- Screen printing on glass

- Napkins with flexo printing

- Broschures with offset printing

UV radiation cures paints and printing inks within seconds and enables quick further processing and high process speeds. Printed products cured with UV are resistant to scratching, abrasion and solvents - product properties that are decisive e.g. for packagings.

Application examples:

- Digital printing for personalised mailings

- Label printing

- Printing on packagings